Color fastness

Color fastness, also known as Color fastness, Color fastness. Refers to the resistance of the color of a textile to various effects during processing and use.

The fastness grade is assessed according to the discoloration of the sample and the staining of the unstained taped fabric. Textiles color fastness test is a routine test item in the internal quality test of textiles.

Textiles are subjected to various external effects such as illumination, washing, ironing, sweat stains, friction and chemical agents in the process of use. Some printing and dyeing textiles are also subjected to special finishing, such as resin finishing, flame retardant finishing, sanding washing and wool grinding, which requires the color of printing and dyeing textiles to maintain a certain relative fastness.

The color fastness

Color fastness referred to as color fastness; The color of colored fibers, fabrics or other coloring materials, in the process of processing and use to be subjected to sunlight, washing, friction, sweat stain and other corrosion resistance.

Colour abundance is rated as grade 5, with the exception of grade R for fastness to old light. The higher the series, the better the color fastness. Leather determination method has two kinds of fading (leather itself color change) and staining L on contact contamination.

Fading test is the color difference between the leather sample and the untreated test sample UU after the sample is treated according to the specified conditions, and the standard gray sample card is used to compare the grading. The staining test is to touch the sample and the standard white cloth according to the specified conditions. The degree of color transfer dyeing of the white cloth by the sample is determined, and the grading is measured by the gray staining sample card.

On color fastness

The movement of dyes from one area to another, usually from the dark to the light, will sometimes occur during storage in garments consisting of different colored parts. This phenomenon is different from sublimation because it occurs at temperatures below sublimation and also occurs with non-sublimation dyes. Mainly reflected in polyester and other chemical fiber fabric migration, other raw materials are also.

Color transfer is mainly due to two reasons: one is the dye transfer, especially the dispersion, reactive dye floating color and fiber migration out of the free dye, may be another sample on the surface of the fiber; Especially the dark to light color dyeing, so as to granular, imprint retained on the surface of another sample. The other is that the fibers fall off under the action of friction and are transferred from one sample to another.

Weep color fastness

Weep color fastness is one of the color fastness, also known as color fastness and resistance to permeability colored fastness, is refers to the dyes on the fabric or residual floating color with the migration of color, mainly reflects the fabric after washing or was the rain caused the dyeing dye stripping and move to the white or light color background cloth on pollution levels, from Japan, in Japan's test is also called the "law".

Color SOB fastness has now become one of the common detection items in Japan, the general requirements to achieve 4 or 4-5 level above, mainly in the dark color, it is often associated with the color fastness, color fastness with good color fastness will also be good.

Testing principle:

One end of the sample is immersed in water with reagents, and the degree of color and SOB pollution caused by the rising effect of water is assessed with pollution ash card. Required test materials: balance, beaker, volumetric flask, normal temperature dyeing machine

Test method:

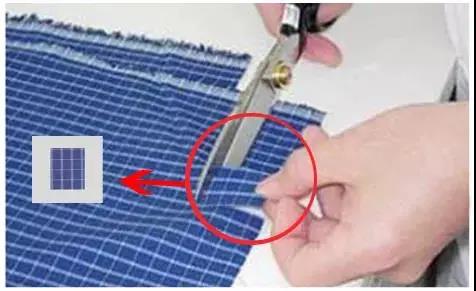

1. Cut a piece of 3cmx5.5cm sample. When the pattern cloth cannot cut all colors into a piece of test material, cut the dark color (the most delicious color).

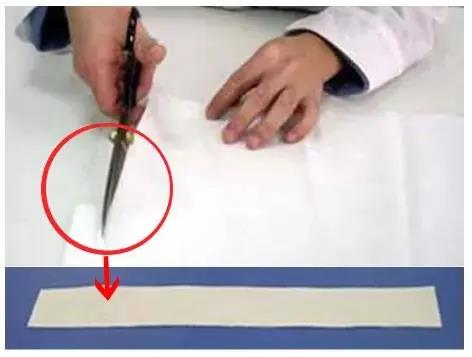

2. Cut the cotton into (length) 20~25cm x (width) 2.5cm.

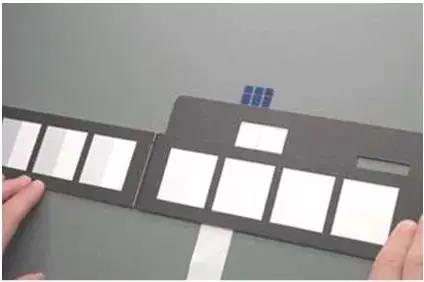

3. Place the test sheet under the cotton tianfu white cloth, and sew a line at both ends where it overlaps by 1.5cm.

4. Deploy non-ionic surfactant solution: Dissolve 0.5g of non-ionic surfactant into 1000ml distilled water.

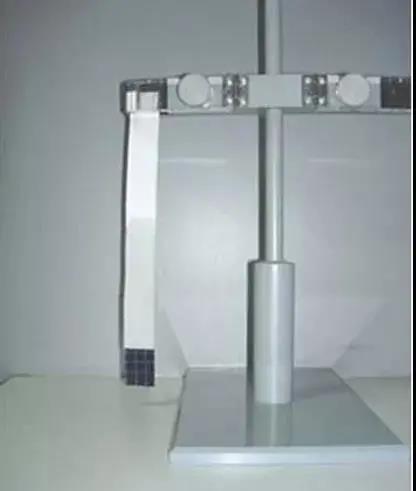

5. Dip one end of the test sheet in the test solution to a depth of 2cm and place it for 2 hours at room temperature according to the standard method of each company.

6. Remove the solution and let the test piece dry naturally in the original state.

7, determination: use the JIS stained gray card to grade the sample (stained white or light-colored parts of the sample).

Tel:0311-87877888 / 0311-87035555 / 13831145889 / 15831121695

Fax: 0311-87810345 Email:duwei@boshitex.com

Add:2309 Shangde Plaza, No. 8 Kangle Street, Xinhua District,Shijiazhuang City, Hebei China

Technical Support:ronglida.net.cn ICP15019912-2